|

| October 08, 2019 | Volume 15 Issue 38 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Wraparound conveyor runs for 5 miles

Continental's closed-trough conveyor system had to overcome complex infrastructural and geographic hurdles across its 8.1-km route through the coal mine in Yangquan, with many tight bends and extreme angles of inclination.

For those readers who like big-equipment applications, here's a neat one. Continental is using a closed-trough conveyor belt system to ensure the smooth and environmentally friendly extraction of pit coal in Yangquan, northern China's Shanxi province. The incredible setup, where the conveyor actually folds over to enclose the material, covers a distance of 5 miles (8.1 km) -- replacing trucking the coal and all the time, fuel, and emissions that goes with it. The closed system minimizes dust emissions, is fireproof, and has low rolling resistance, which makes it particularly energy efficient.

There are many types of pipe conveyor belts, but the standard design has a flat or slightly rounded conveyor moving inside a closed pipe. The Continental solution goes one further by making the conveyor belt turn into the pipe. The outside edges of the belt overlap throughout the entire duration of transportation like a protective casing for the transported material. Only when taking up and delivering material do the closed-trough belts open up and assume the shape of a conventional conveyor belt.

In Yangquan, the Continental tube conveyor, with a width of 1,600 mm (63 in.) and an outer pipe diameter of 458 mm (18 in.), transports 1,000 metric tons of coal per hour and 2.4 million metric tons of coal per year. "This results in an enormous saving of 2,880 metric tons of coal dust emissions per year -- and thus significantly improves air quality," says Stephan Weisgerber, General Management, Continental in China. "Our system also protects the health of mine workers and improves the quality of life of the people living in the area."

The closed-trough conveyor belts in Yangquan are also flame retardant, adding another layer of safety.

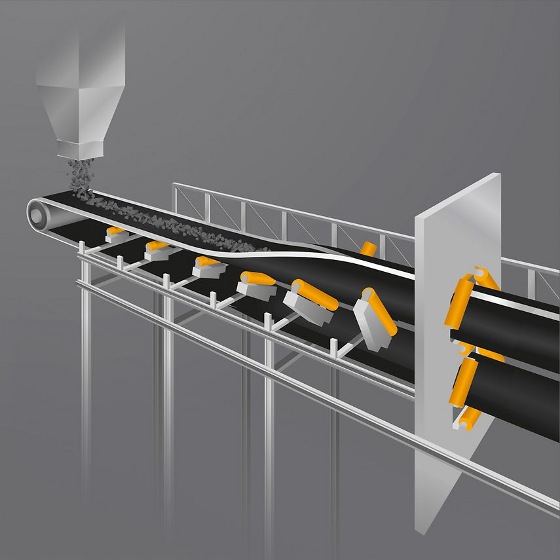

The Continental closed-trough conveyor belt system is troughed at the loading point and can be filled like a conventional conveyor belt. Once the material has been loaded, specially arranged finger rollers ensure that the conveyor belt forms a closed circular belt. Further hexagonal idler stations along the conveyor route ensure closed guidance of the belt. As a result, the conveyed material is continuously protected by the closed belt system. At the end of the belting, the closed belt is opened by the arrangement of the idlers and takes on a flat shape on the pulley in order to unload the conveyed material, just like on conventional belt conveyor systems.

The system was devised with the help of conveyor manufacturer Sichuan Zigong Conveying Machine Group. One particular challenge in an application like this is the precise transverse rigidity, which ensures a good tube shape so that the belt does not collapse. If the rigidity is too high, the belt moving resistance will be too high -- and energy consumption will rise.

The Continental closed-trough conveyor belt system is troughed at the loading point and can be filled like a conventional conveyor belt. Specially arranged finger rollers ensure that the conveyor belt forms a closed circular belt when needed.

Shanxi's coalfields account for 37 percent of the province's total area. There are approximately 200 billion metric tons in the area, which roughly equates to one-third of China's coal deposits (source: China Tourism). Much of the province is more than 1,000 m above sea level. Consequently, the 13.37-km2 mining area of YanKan Coal Ltd. in Yangquan, which is equivalent to approximately 1,870 football fields in size, is also hilly and almost impassable.

In mining, whether above or below ground as well as in industrial applications, large inclines and tight bends with low space requirements and high mass flows must often be overcome. While the angle of incline of traditional troughed belt conveyors is usually 20 degrees or less and curve radii remain very large, a pipe conveyor of Continental's design allows curve radii and tilt angles up to 30 percent.

The Yangquan closed-trough conveyor belt overcomes elevation differences up to 172 m over its 8.1-km stretch from the coal deposit to the transfer station, going through a complex route with over 39 convex, concave, and 20 horizontal bends.

"Our closed-trough conveyor belt easily masters tight bends and steep conveyor angles and thus adapts perfectly to the landscape to save space," says Ming-Ya Tang from Continental. "Our system is characterized by the fact that it manages without transfer points."

This also has a positive effect on the installation costs of the assembly, which are generally cheaper than for assemblies with transfer points.

In Yangquan, the closed-trough conveyor belt system transports pit coal at a high speed of 4 m/s or 14.4 km per hour -- about three times the speed of a pedestrian walking briskly or a cyclist riding at a moderate pace. But miles of conveyor belts can consume as much electricity yearly as a whole town. To address the energy usage, Continental uses a special rubber compound to minimize the rolling resistance of conveyor belts, which significantly reduces the system's energy consumption. Energy demands increase when the belt runs over the idlers, which account for two-thirds (and therefore the largest share) of the total resistive forces of the conveyor system.

Hexagonal idler stations along the conveyor route ensure closed guidance of the belt, protecting the conveyed material.

"With the right compound, we reduced the energy consumption involved in transporting raw materials by 25 percent," says Weisgerber. "This special compound is also used in the facility in Yangquan. This will improve the facility's carbon footprint and save on energy costs for the operator."

In an eye-popping comparison, the energy saved in just 1.5 hours of use for such a conveyor is about as large as the average annual consumption of a household in Germany (3,171 kWh) or that of five households in China (confirmed by the Institute for Transport and Automation Technology of the University of Hanover in Germany).

Continental closed-trough belt conveyors have already proven themselves in many places in China -- in coal mines as well as in power plants and steel mills. Yangquan's Shangshe coal mine has a 4.9-km closed-trough conveyor belt system in operation. At the Anyang coal mine in Chenghe (Shaanxi province) and the Hongyuan coal mine in Puxian (Shanxi province), there are also four pipe conveyors, with a total conveying length of 8.7 km. More projects are in the works.

Learn more about Continental conveyor systems here.

Source: Continental

Published October 2019

Rate this article

View our terms of use and privacy policy